Methane

REI Drilling, Inc.’s expertise in methane drainage stems from its commercial coal mine methane project at the Soldier Creek Mine in Carbon County, Utah, which operated from 1982 to 1994. This was the first project to recover and commercially sell coal mine methane via pipeline injection, using long, in-seam directionally drilled boreholes developed in advance of room and pillar mining in the USA. Building on this foundation, REI established a dedicated contract directional drilling division, providing methane drainage services (including other applications of directional drilling) to the underground coal mining industry. REI Drilling, Inc. engineers each of its methane drainage projects, from identifying the source of the underground methane emissions to designing the appropriate methane drainage approach. Key project considerations include geologic conditions, reservoir characteristics, geo-mechanical properties, in situ and mining induced stresses, hydrology, mining technique, and mine plans. REI Drilling, Inc. employs reservoir simulations to plan boreholes that meet gas content reduction goals within the required timeframe, estimate gas production, and specify gas collection infrastructure—both underground and at the surface—for monitoring, use, or destruction. With nearly 45 years of experience, REI Drilling, Inc. is widely regarded as a leading provider of comprehensive methane drainage solutions, from system design through project implementation, and gas management.

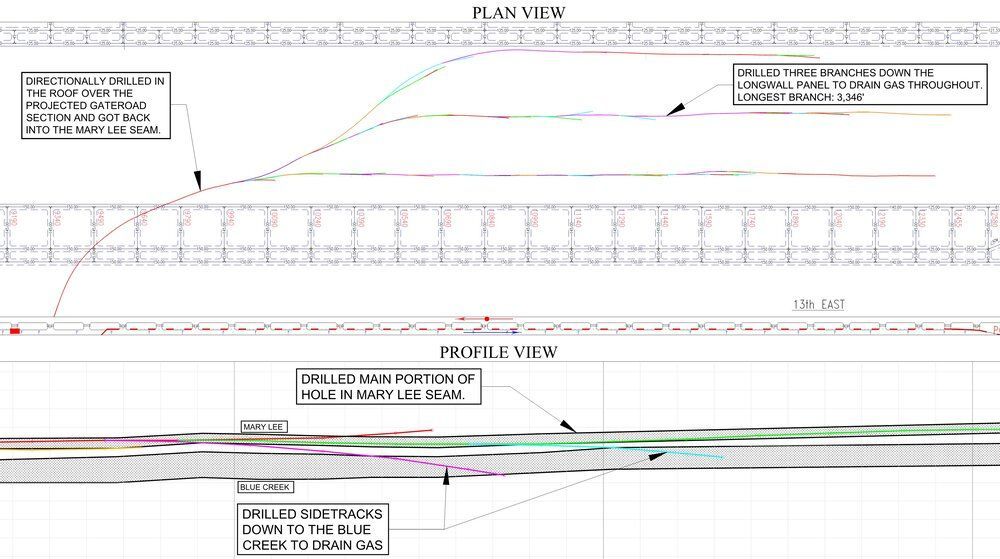

Longwall Degasification

Download Case Studies

Download Case StudiesUsing directional drilling techniques, REI has the capability to drill along specific projected paths in order to drain methane from a longwall panel efficiently from fewer setup locations than traditional non-directional cross-panel drilling. Boreholes can be intentionally drilled adjacent and parallel to future gateroad entries to improve mining efficiencies and safety on development units.

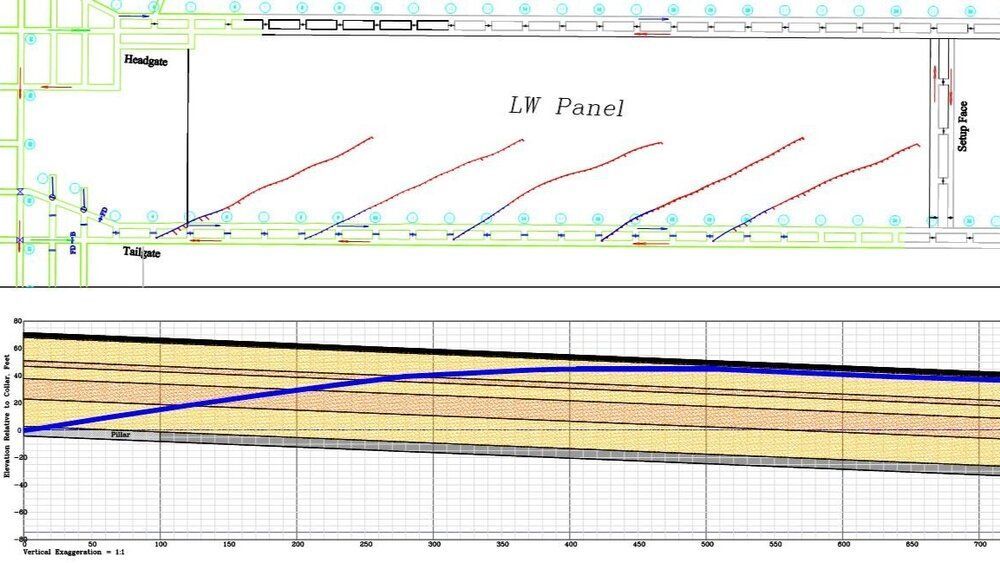

Gob Degasification

Download Case Studies

Download Case StudiesREI uses directional drilling to install horizontal laterals in the overlying fracture zone and tie the hole into existing vertical gob wells using vertical well intercept techniques. This application increases the coverage area and efficiency of the vertical gob well, which is particularly useful when surface access is limited for new vertical gob well installations.

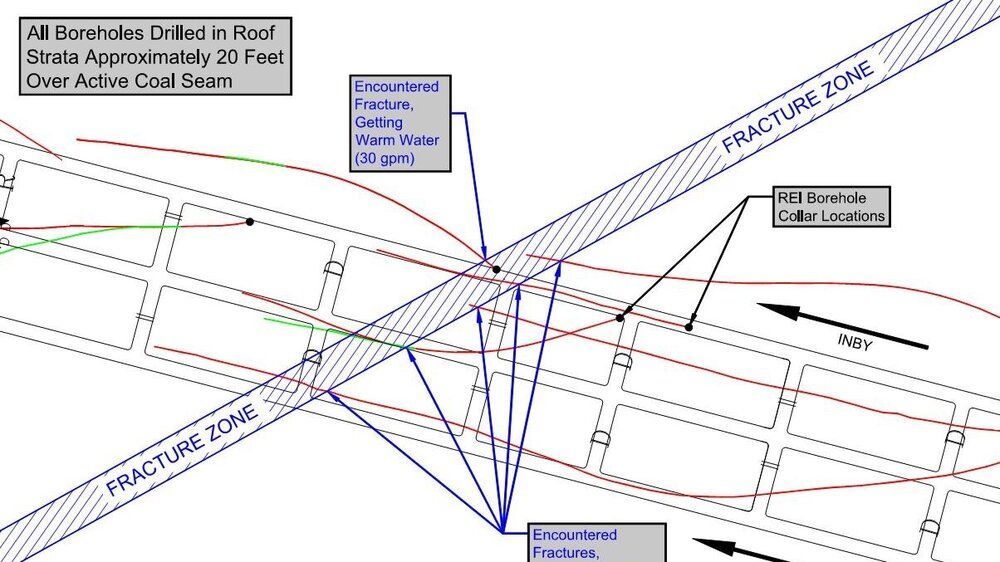

Feature Focused Gas Drainage

Download Case Studies

Download Case StudiesUsing directional drilling techniques, REI can align a horizontal borehole with future mine heading projections and intercept charged geologic features and fractures in advance of mining, allowing these features to be safely depressurized in a controlled manner. REI uses pressure tested casing and a contained wellhead complete with a blow-out preventer to ensure full control at all times.

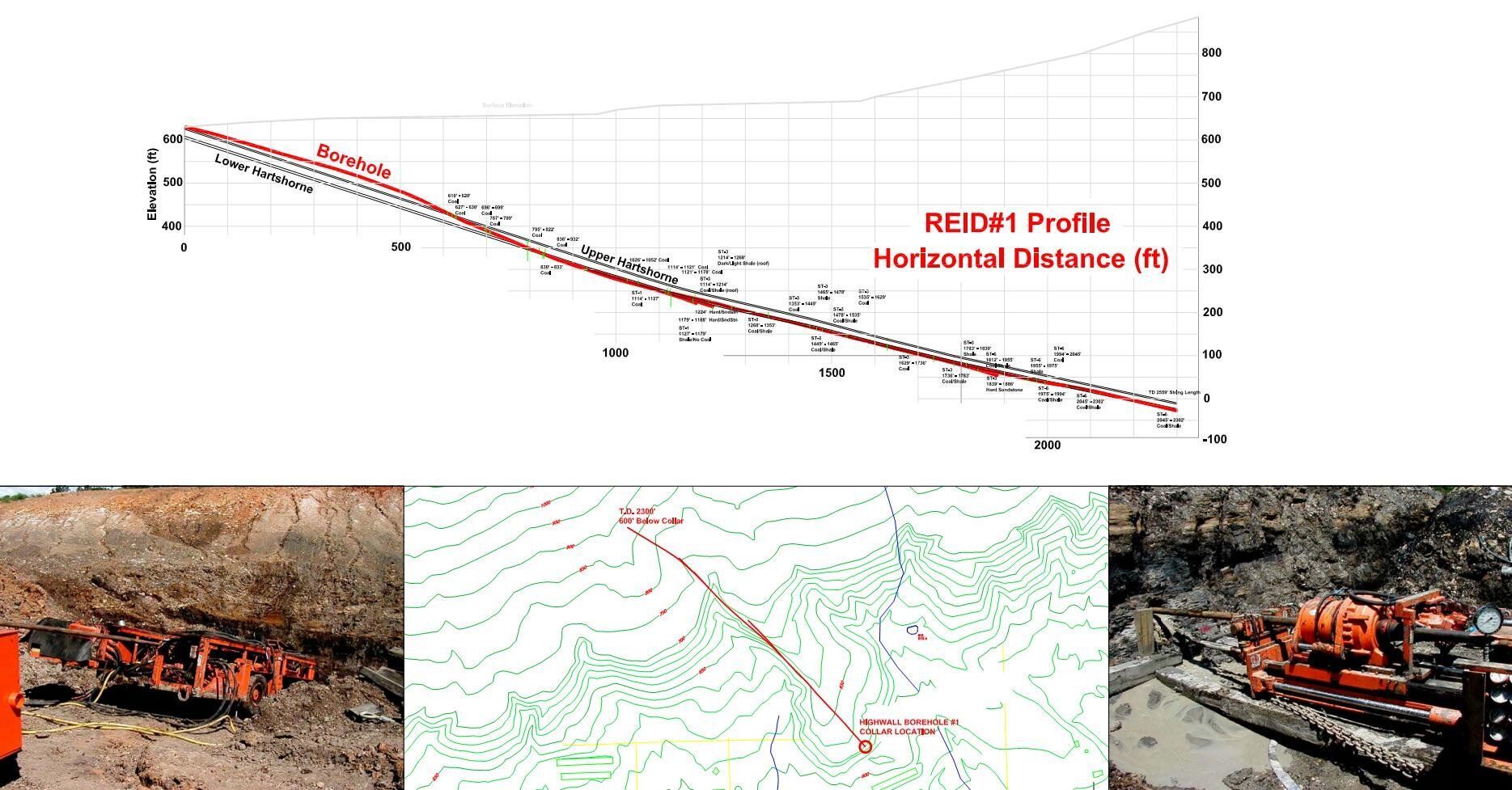

Commercial Coalbed Methane Recovery

Download Case Studies

Download Case StudiesSince its inception, REI has drilled for coalbed methane (CBM) production and commercialization, including surface and underground drill setups. We install directional boreholes to drain methane from your reserves in a safe, controlled manner to improve future mining efficiency. Also, through our established business relationships, we can ensure your produced methane receives the best price, either through gas sales or a carbon credit program