Drilling Expertise & Engineering Prowess

Dewatering and Depressurization

Water Transfer for Sump Consolidation

REI installs directional holes between sumps to allow for pump-free gravity drainage so mining clients only need to manage water produced at the lowest sump. Minimize long-term pumping and infrastructure costs by consolidating sumps with gravity drainage boreholes.

Water Drainage Boreholes for Sump Consolidation Cross Panel

Gateroad Water Transfer Plan

Proactive Dewatering for Underground Mines

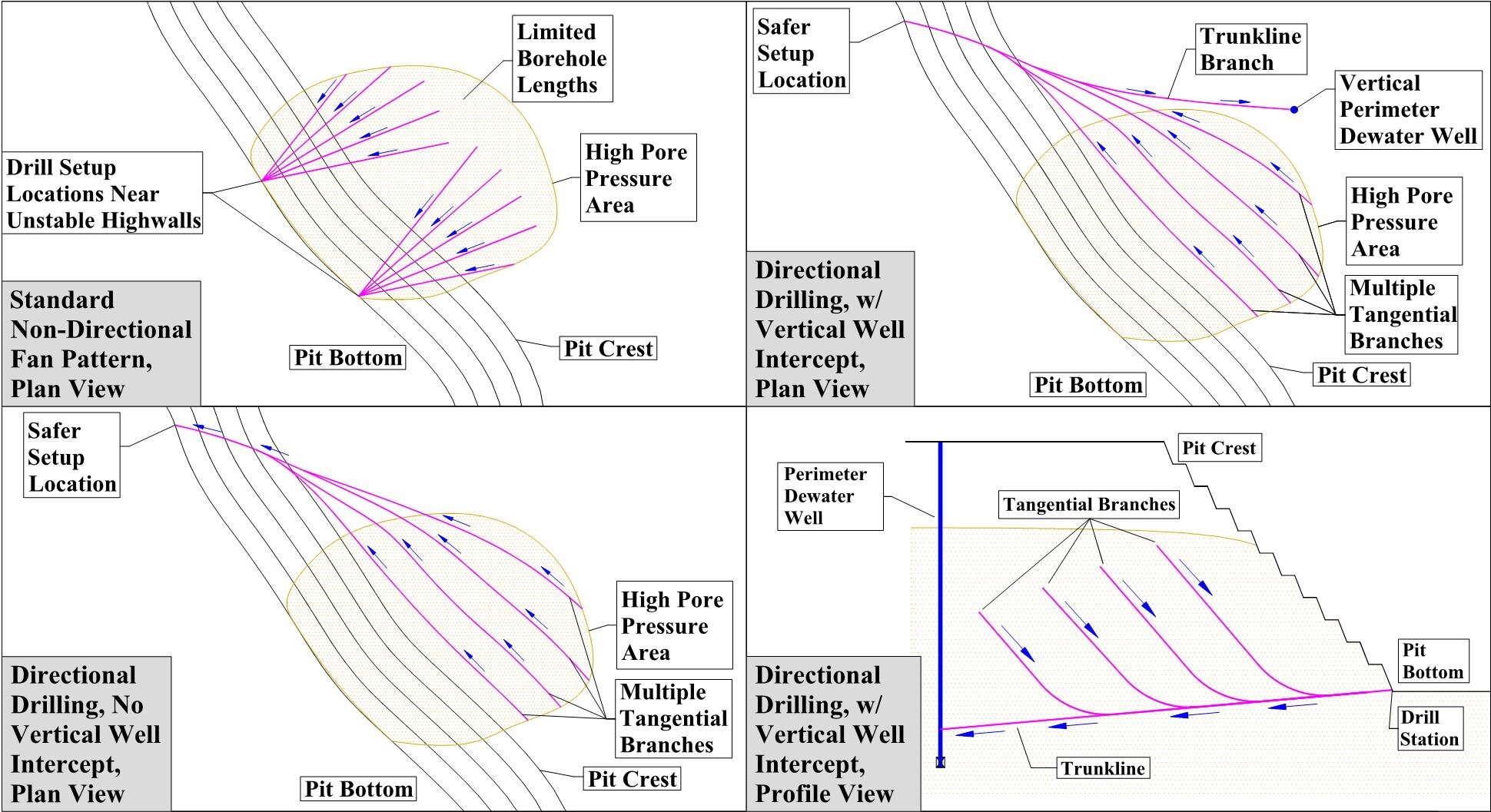

Directional drilling has several key advantages over traditional non-directional drilling techniques when dewatering strata in advance of mining. Holes can be maintained within a targeted strata layer or steered to intercept water-bearing features at intentional angles that maximize hydraulic connectivity and drainage. In addition, sidetracking capabilities allow for maximum coverage from fewer borehole collars and setup locations. More novel applications include vertical well intercepts to drain water collected in horizontal laterals to a production well.

Proactive Water Drainage Plan

Directional drilling dewatering plan

Dewatering Overlying Mines

For thinner interburden distances, MSHA safety regulations require draining of overlying mine workings prior to undermining. Use directional drilling from underground setup locations to install gravity drain boreholes, utilizing the mine’s existing infrastructure and preventing the need for surface drilling permits and developments. REI uses pressure tested casing and contained wellheads, including blowout preventers, to fully control water flows at all times.

Dewatering Overlying Mine Workings

Highwall Depressurization

Directional drilling expands traditional highwall depressurization horizontal drilling capabilities by (1) allowing for longer boreholes, (2) steering to intercept water-bearing features at intentional angles that maximize hydraulic connectivity and drainage, and (3) installing sidetracks to increase coverage area. In addition, the increased design capabilities can allow for more alternative drill setup locations in safer highwall areas that are less intrusive of active mining operations. A more novel application includes vertical well intercepts to drain water collected in horizontal laterals to a production well, shifting the burden of water handling to outside the active mining pit and reducing concerns with freezing at the highwall in colder environments.

Comparison of Highwall Dewatering (NonDirectiona)l vs Directional with Vertical Well Intercept

Highwall Drainage From Bench Diagram

Groundwater Monitoring and Sensor Installation

Use directionally-steered holes to place your sensors and monitoring equipment in areas where traditional non-directional holes may not be able to reach. With our focus on directional drilling, we can assist developing an installation plan using steered boreholes. Ask us about using directional techniques to install groundwater sensors and monitoring equipment, including vibrating wire piezometers, time-domain reflectometry, fiber optic, and wireless piezometer and spatial location sensors.

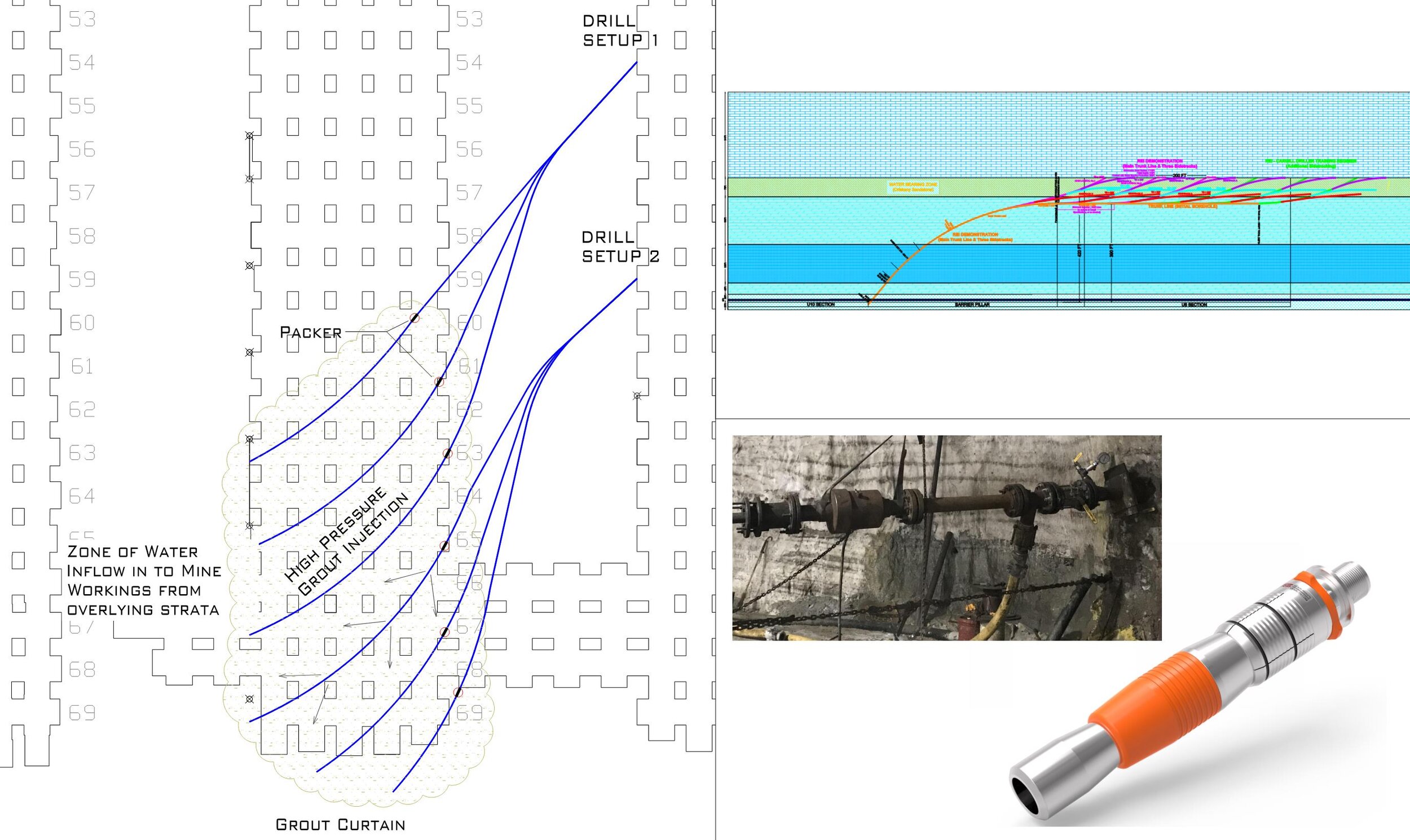

Grout Curtains

Use directionally drilled boreholes to install effective grout curtains that shield your workings from high inflows. Boreholes may be placed in overlying or underlying strata, aligned with projected entries or tunnels, or steered to intercept water-bearing features. Single boreholes or multi-lateral boreholes may be developed to maximize coverage area and formation of a grout curtain. High pressure grout pumps are utilized to inject grout into formations through a sealed standpipe or through downhole packers.

Grout Injection Into Overlying Strata